Quality starts at the Beginning – Not The End

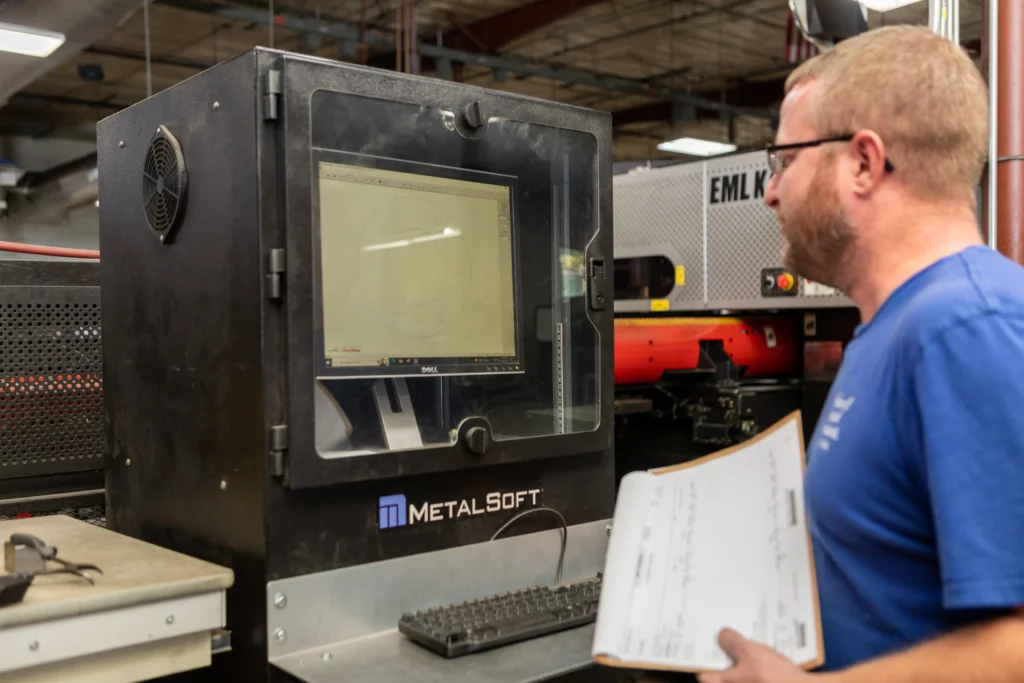

Starting with the most detailed part, Midwest Metal Products programs all dimensions directly into our CNC equipment. And throughout the manufacturing process, each job is monitored by Statistical Process Control (SPC)-trained employees to maintain efficiency and accuracy.

- FabriVISION® high-speed laser scanning authenticates flat layouts prior to production

- Brown & Sharpe Coordinated Measuring Machine (CMM) for accuracy verification to 0.005″

- FaroArm® mobile inspection station verifies formed dimensions to 0.002”

- SPC-40 PC Shop Floor Network, with readings taken at all major steps to ensure compliance

- 5S Lean Manufacturing culture

No matter how intricate the design, Midwest Metal Products can provide unmatched precision for all your custom fabrication requirements — every order, every time.

See It For Yourself

Take a quick video tour to see our quality control technology and processes in action. Then request a quote online or contact the Midwest Metal Products team for more information.

Learn More About Us