Precision work – every order, every time.

So what is it that sets MMP apart from other vendors?

- 8,000 square feet of dedicated production space

- Five-stage pretreatment lines

- Automatic conveyors

- Infrared ovens

- Unsurpassed quality control

Metal Painting and Powder Coating Durability

Powder-coated metal provides a durable finish to equipment that can last for decades. Unlike painted metal surfaces, powder-coated metal can remain intact and rust-free for up to 20 years.

Powder coating is resistant to chemicals, corrosion, and weathering. Coating and wet painting/plating can both offer you a finish to your product which will be both functional and appealing.

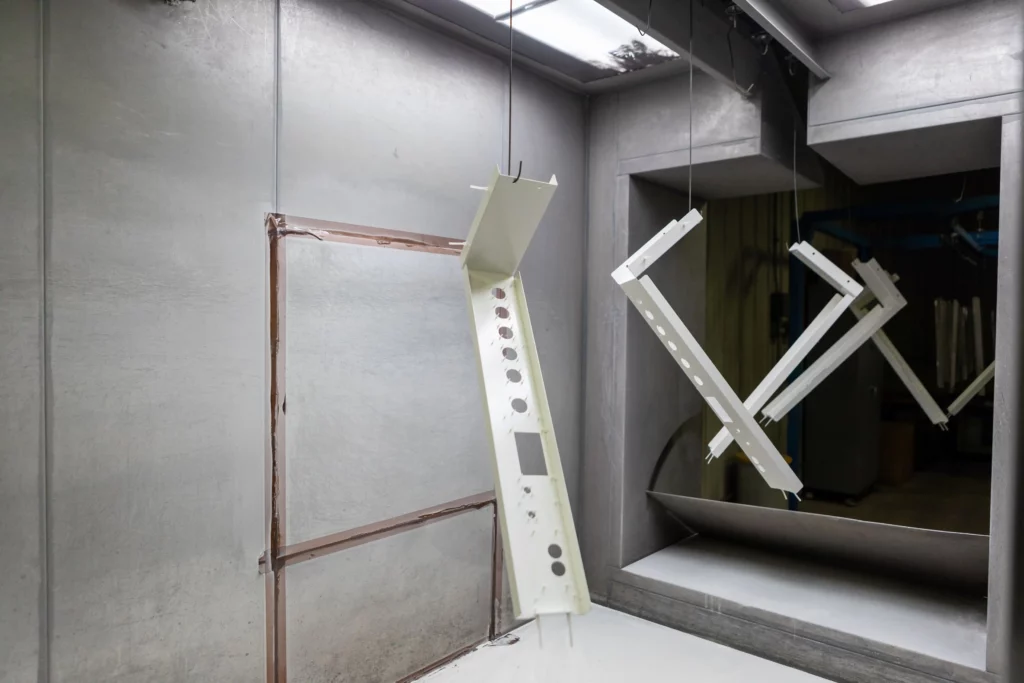

Take a look through the photos below for detailed views of our finishing capabilities.

Benefits of powder coating

- Yields thick, hard finish that is tougher than traditional paints.

- Electrostatic stage greatly increases the efficiency and productivity of coating by nearly 95%, less paint is wasted and the metal object is fully coated. Powder coating has a one coat finish.

- It creates an even flat surface, the powder is sprayed and heated without drips or application traces.

Drawbacks of powder coating

- The thick finish it produces can be a drawback depending on your needs

- Can be expensive for smaller jobs. Powder coating requires spray materials, electrostatic booth and an oven.

Benefits of wet paint and plating

- Ideal for products which cannot be heated for powder coating, powder coating requires an oven while wet paint finishing does not.

- Wet paint has a wider color selection, so if you have a custom color job wet paint is probably the way to go.

- Produces a thinner finish than powder coating.

- It is an economic finishing process.

Drawbacks of wet paint and plating

- Not as durable as powder coating.

- Can require multiple finishes to get an even, perfect finish.