What is Sheet Metal Fabrication?

When considering the highest technological advancements of the last century, one imagines lasers and computers. Movies like Star Trek and The Matrix hold promises of technologies that seem already designed today. In a field of technology that includes microcomputers no bigger than a snowflake (April 26, 2014, New Scientist) or lasers the size of three football fields with the capacity to momentarily replicate the power of the sun (February 15, 2014, Science Magazine), it is easy to overlook an industry that combines old-world tradition with new-age technology. Even though the field uses plasma and laser cutting or Oxy-acetylene torches, the products are often not given the attention they deserve. Sheet metal fabrication is a complex balance between the reliable processes of yesteryear and the technologies of tomorrow.

By learning about metal fabrication, one can appreciate the products of metal fabrication and fabrication capabilities. Metal fabrication is an important factor in many major industries: aviation, electronics, and medical equipment among others. In the aviation industry, sheet metal fabrication is important from the cockpit to the cargo bay of aircraft—wing to wing. Sheet metal fabrication has contributed to almost every major advancement in the electronics industry by providing the literal backdrop of these technologies; metal fabrication serves as the encasing of electronics and the panels on which these electronics occur. In the medical industry, sheet metal fabrication is involved in nearly all medical devices and tools. Knowing about sheet metal fabrication can be a matter of life and death in some contexts.

Fabrication Techniques

Metal fabrication is the process by which sheet metal structures are created through multiple stages: cutting, bending, and assembling. Cutting involves sawing, shearing, chiseling, torching, or numerical control cutting (such as a laser or water jet). Cutting is the process by which the size of the metal is determined. Bending is done by hammering or press-braking. Bending is the process by which the shape of the metal is determined. Assembling involves welding, binding with adhesives, riveting, threaded fasteners, or crimpled seams. Metal fabrication is a combination of techniques borrowed from blacksmithing, boiler-making, milling, and steel-working.

Fabrication Specialties

In considering metal fabrication, one must think about the specialties associated with sheet metal fabrication. Sheet metal fabrication is a constantly evolving field with a multitude of technological innovations. The following is a sample of the many advanced specialties of metal fabrication.

- Welding: This is a cost-effective way to get precise manipulation of steel, stainless steel, and aluminum.

- Powder coating: This is a finishing technique of sheet metal fabrication in which the metal product is covered to alter the finish and/or color of the product. This can be a particularly useful tool in assuring a product adheres to governmental standards and regulations.

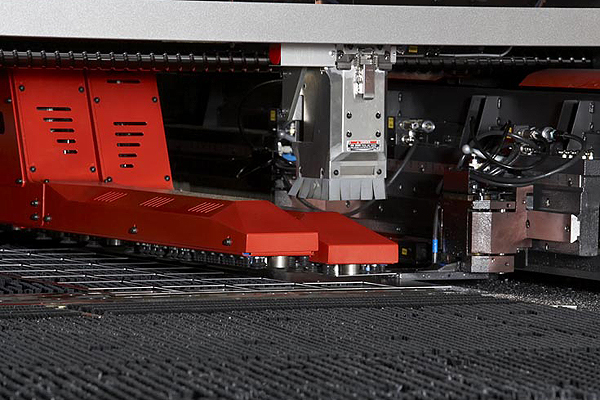

- Turret/lasers: This is an automated process by which metal projects are completed at a high speed with precise accuracy.

- Sub-contract manufacturing: The process by which the complex process of sheet metal production is divided up so that specific tasks are completed separately so that a particular component of the larger sheet metal fabrication is completed outside of the rest of the production.

- Prototyping/machine design/technical drawing: These are the processes by which metal fabrication can be customized to meet particular needs.

Metal Fabrication Projects

The metal fabrication capabilities are seemingly endless. Fabrication is key in producing aviation gauges, such as the casing for these meters. Metal fabrication is needed for the construction of many aviation instruments. These necessary tools for aviation rely heavily on fabrication for housing and operation. Sheet metal fabrication is largely responsible for the production of metal devices, particularly electronic ones. Most of the equipment in a hospital or doctor’s office is dependent upon metal fabrication—from apparatus to monitor the heart to x-ray machines to look inside the body. From the ground to the air, metal fabrication projects are everywhere and the fabrication capabilities are seemingly endless. Any plate or panel needed for a product can be designed and constructed to meet any necessary specifications. And with custom design projects, the technology of metal fabrication can get someone anything he or she can imagine…even the cool technologies of the movies.