Powder Coating vs. Wet Paint and Plating

The world is made of important binaries: men versus women, good versus evil, conservatives versus liberals among many others. While most of these opposing forces receive much public attention in a matinee board-style grudge match, some of these binaries only surface as they become important in specific choices. In the world of sheet metal fabrication, the grudge match between the best finishing techniques for an individual product is determined in a split decision. The match between powder coating against wet paint and plating is far from unanimous…and is instead decided on a case-by-case basis. In order to better understand which sheet metal finishing technique is best for the manufacturing of your product. By understanding the basic principles, processes, and benefits/drawbacks of both coating and wet paint/plating, you can design your product to knock out all others.

Powder Coating

Powder coating is a finishing process in which a coating is applied electrostatically to a surface as a free-floating, dry powder before heat is used to finalize the coating. The powder can be made of any number of products: polyester, polyurethane, polyester-epoxy, straight epoxy, and acrylics. Powder coating is a finishing process that yields a thick, hard finish that is tougher than conventional paints. Powder coating can be found on a range of products, from household appliances to automobile parts.

The Process

Powder coating can be accomplished through one of two processes: thermosets and thermoplastics. Thermosetting involves additional chemicals that react to the powder during heating. Thermoplastics have no additional chemicals and instead, just melt and flow into the final coating. Both processes of powder coating look quite similar except for this distinguishing feature. The thermoset or thermoplastic powder is created by taking the powder input and binding the items together. Secondly, heating the mixture, rolling out the product, and then breaking the polymer product into chips. Finally, can be ground into a fine powder.

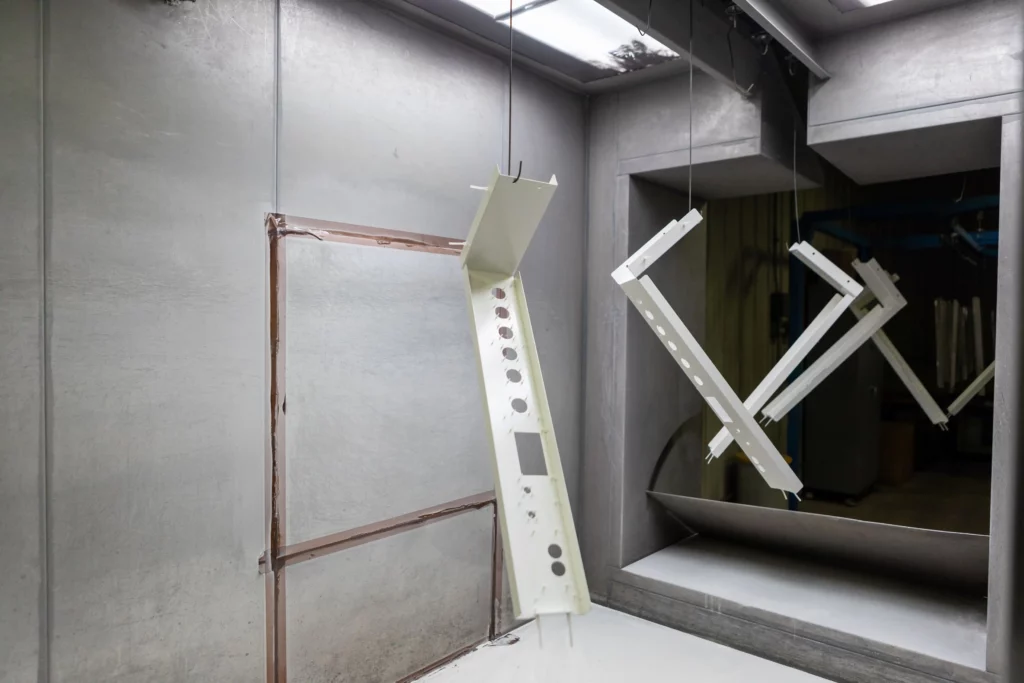

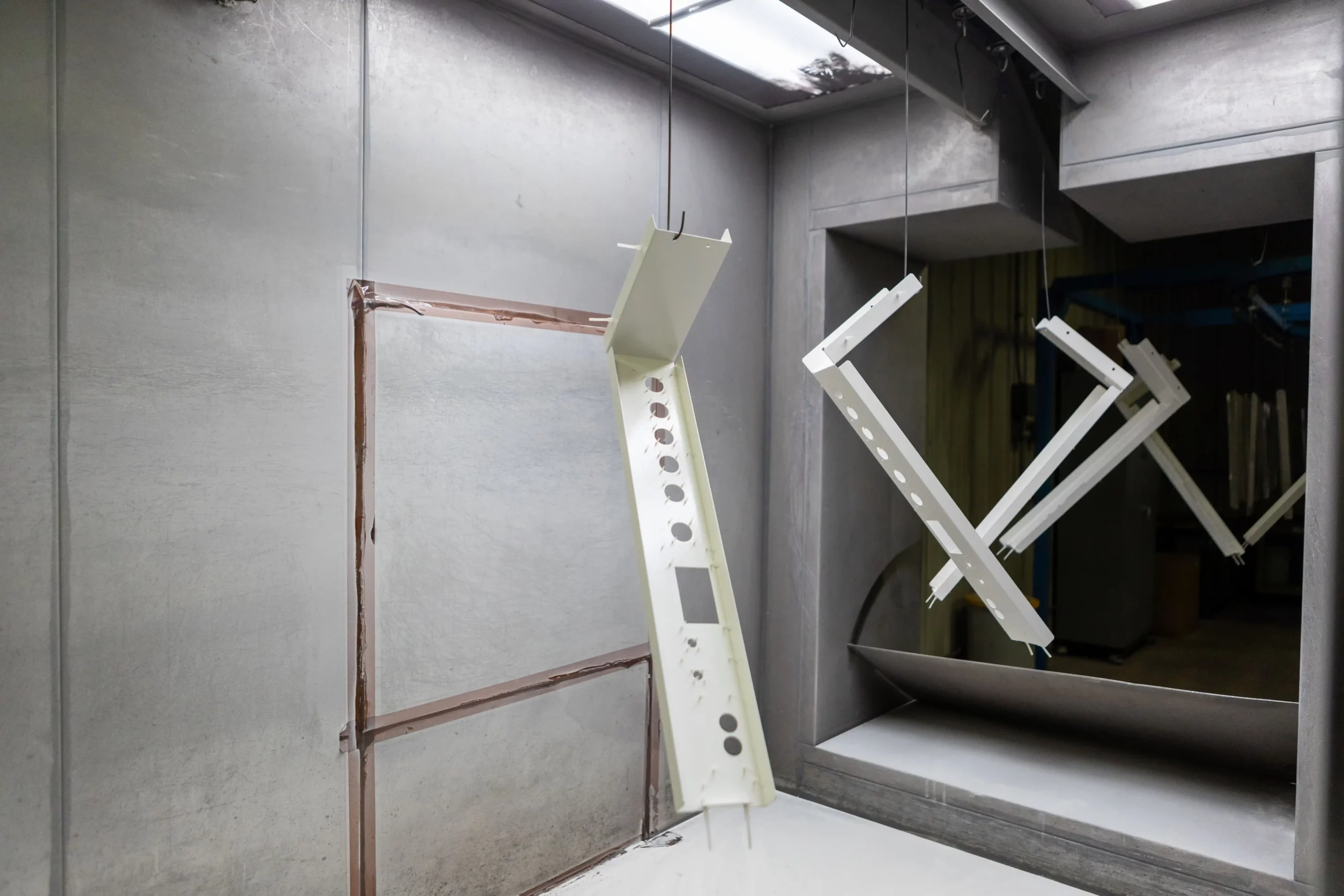

Each of the processes of powder coating is typically after the powder is created by preparing the metal to be coated. The object is cleaned with particular attention to the removal of any debris and oil which can inhibit the attachment of the dry powder. Next, the dry powder is applied electrostatically—a process by which the particles of the powder and the object are charged through a high-voltage electrostatic surge. This electrostatic stage of powder coating greatly increases the efficiency and productivity of the coating process by nearly 95%. Less paint is wasted and the metal object is fully coated.

The sprayed powder coating is then cured at temperatures as high as 400 degrees for ten minutes so that the finish can set onto the object. While setting, the powder melts and flows around the object. The heat not only melts the powder but binds the polymer into a heavier polymer that bonds in a tight network-like finish. The curing not only coats the sheet metal product, but it also binds the polymer into a tighter, heavier finish.

The Benefits

The benefits of the process of powder coating are numerous. First, powder coating results in a thick, dense finish on metal products which can be more durable and longer-lasting than conventional painting. Second, powder coating is typically a one-coat finish so the process can be quite quick and easy. Third, powder coating can include multiple custom finishing colors and textures as the powders that are sprayed onto the item can be expertly manipulated. Fourth, powder coating is an environmentally safe finishing process because it produces few volatile organic compounds. Finally, powder coating creates the most even finished surfaces (horizontal and vertical surfaces) because the powder is sprayed and heated across without drips or application traces.

The Drawbacks

There are two major drawbacks to the powder coating process. First, powder coating produces a thick finish to metal products. It can be quite difficult for this coating to produce thin finishes, particularly because as the polymer is thinned it tends to produce a bumpy texture similar to the peel of an orange. Second, smaller sheet metal jobs might prefer a less expensive or complex finishing process. Powder coating requires spray materials, an electrostatic booth, and an oven—all items which can be expensive and involved for smaller projects.

Wet Paint and Plating

Wet paint is the traditional (although technologized) process of applying liquid paint to a metal product for finishing. Most sheet metal fabrication processes will use a spray, pump, or pressurized vessel to deliver the wet paint evenly. Plating is the process by which metal is deposited on a conductive surface. (Think of how jewelry can be gold-plated.) Plating can be used for many purposes: decoration, corrosion inhibition, improve wearability, harden, reduce friction, or improve paint adhesion.

Wet Paint Process

The process of wet painting is accomplished by thoroughly cleaning a metal object before wet-blasting liquid paint to an even thickness of approximately 15-20 micrometers. The wet paint is applied until the product is evenly coated with the desired thickness of the paint. The process of plating can be quite complicated and depends on the desired metal for plating and sought effect. Typically an item is covered with the desired metal and some combination of heat and pressure are applied to fuse them—although vapors, vacuums, and liquids can also be used as adequate substitutes to the heat or pressure of traditional plating processes.

The Benefits

The benefits of wet paint and plating are quite complementary to coating. First, wet paint is ideal for products that cannot be heated for powder coating. Wet paint does not require an oven for finishing. Second, wet paint can produce a wider range of colors than powder coating so more custom color work could require spray painting and plating. Third, wet paint and plating can produce a much thinner finish than powder coating. Products that demand a thin finish can benefit greatly from wet paint. Finally, wet paint is a much more economical finishing process, particularly for smaller jobs.

The Drawbacks

There are two major drawbacks to wet paint and plating. First, wet painting is not as durable as powder coating. Wet paint can require maintenance and re-finishing later. Second, wet painting can require multiple coats to get an even, unmarred finish. Because wet paint begins with a liquid, the finish can be tricky to guarantee the perfect finish. Therefore, results in multiple finishing coats.

What is Best for Your Application?

Deciding a winner for the great coating versus wet paint and plating battle for your products can be a difficult decision. Ultimately, you will want to consult an expert who can help you consider all of the possibilities with special detail to the needs of your company, your customers, and your product. Coating and wet painting/plating can both offer you a finish to your product which will be both functional and appealing.